Every operation reflects our commitment to excellence.

- +85 155 596 1658

- Losangle, Street Road 24, New York, USA - 67452

- support@gmail.com

Every operation reflects our commitment to excellence.

ABOUT US

ABOUT US

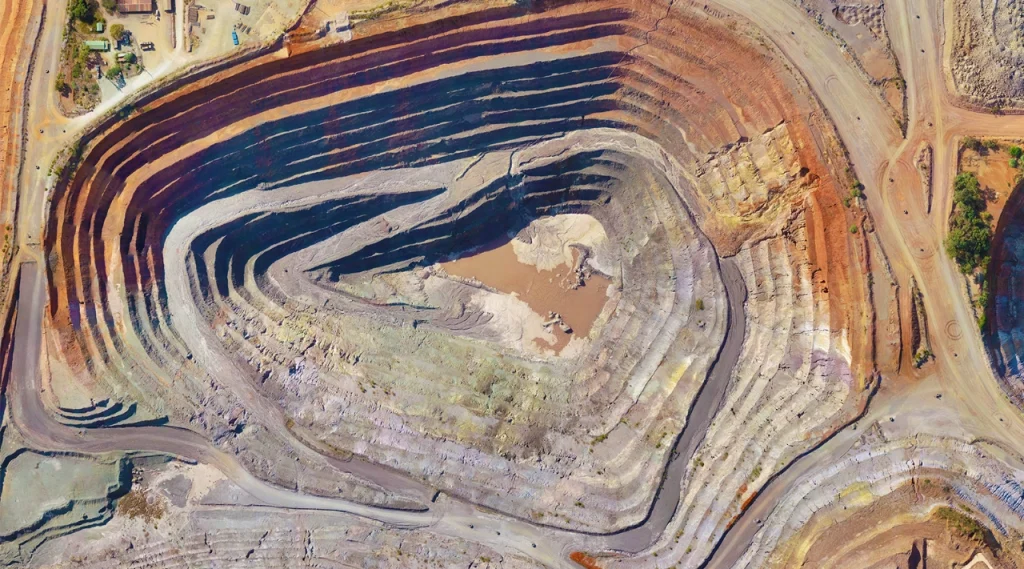

Based on detailed geological assessments, ore quality, and resource stability, Kumasi’s mining sites are developed with long-term sustainability and high recovery potential in mind. Our primary deposits hold strong reserves with consistent grades, supporting an estimated mine life of over fifteen years. Through precise direction, dip, and grade control, Kumasi ensures efficient extraction and maximum utilization of recoverable minerals across multiple open-pit zones — combining advanced techniques with responsible mining practices.

Business Experience

At Kumasi, we utilize advanced yet fundamental mining techniques such as fragmentation (drilling and blasting), material handling, stockpiling, dewatering, and haul road reclamation. Each stage is executed with precision to ensure safe, efficient, and sustainable operations.

Our processing chain follows a streamlined sequence — crushing, grinding, leaching, and solid-liquid separation, supported by solvent extraction and electroplating — to achieve high recovery and superior product quality.

In addition to mining and processing, Kumasi operates an integrated network of facilities including an acid plant, cobalt processing unit, tailings leach system, gravimetric concentration (DMS) plant, tailings storage ponds, and heap leaching units.

As we gradually transition from oxide to sulphide mining, Kumasi is investing in the development of state-of-the-art sulphide processing facilities to further enhance efficiency and resource recovery.